562

562

A BMS is a system that manages Li-Ion battery packs through integrated firmware and hardware.When paired with telematics,it provides real-time data on the status and health of your forklift battery.

Lithium-ion batteries have many advantages over lead-acid batteries.They are lighter,more efficient,charge faster and last longer.However,they are susceptible to external conditions,and BMS can detect,control,and manage the battery pack to make the battery perform better.

A typical battery management system usually includes the following functions:

Battery monitor

Battery voltage monitor

Battery voltage balancer

Temperature monitor

In this article,we'll highlight the capabilities of a battery management system and explain why it's an essential part of lithium-ion batteries.

Not all Li-Ion batteries have or require a battery management system.Some Li-Ion batteries employ a cell balancer that only optimizes the cell voltage and prevents overcurrent and undercurrent while charging.

Battery balancers exist in different Li-Ion battery applications such as notebook computers.The only purpose of a battery balancer is to ensure that the cells in the battery have the same state of charge.

On the other hand,BMS is almost used for batteries that power industrial equipment.A BMS is required to monitor important parameters such as ambient temperature or the state of charge of the battery during operation.

Because lithium-ion batteries are manufactured with different capacities,each battery may be in a different state of charge.

Both the cell balancer and the BMS will distribute an equal charge to each cell in a Li-Ion battery.The downside of a battery balancer is its limited functionality compared to a battery management system.The cell balancer cannot monitor other important parameters such as:

Temperature changes

Overcharge and overdischarge

Charging status

Compared to a battery balancer,a battery management system can do more than just balance batteries.BMS is designed to manage temperature changes,charging habits,state of charge.

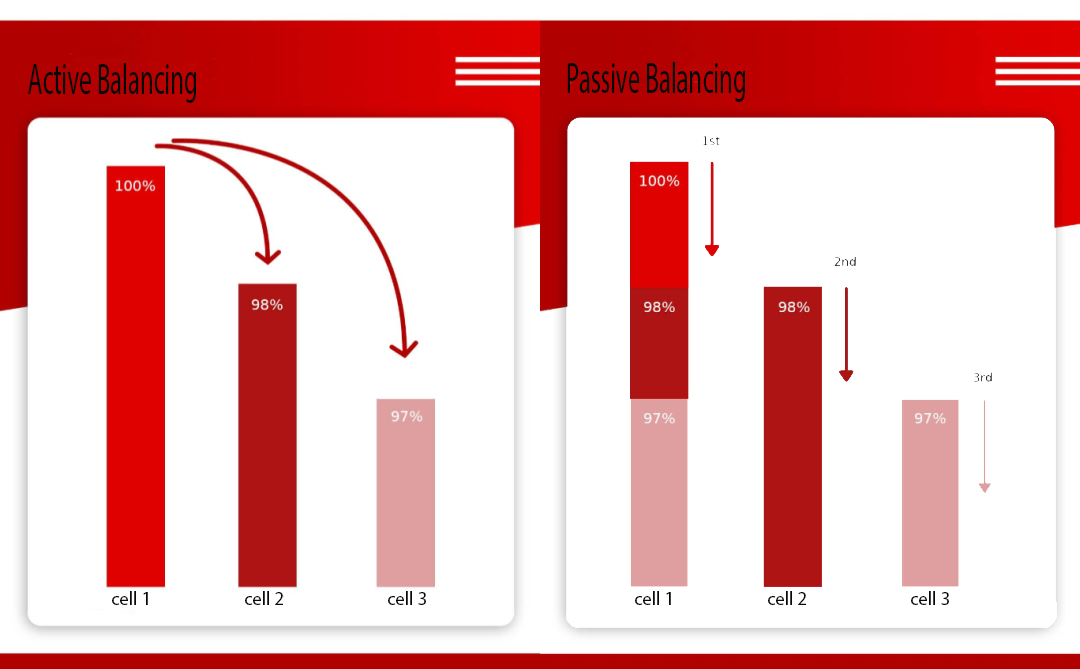

Active Balancing–The BMS distributes charge from high-charge cells to low-charge cells.

Passive Balancing–BMS drains high charge cells first and allows all cells to have the same state of charge.

Both methods can balance the state of charge,but each has its pros and cons.Balancing the charge of a multi-cell battery pack is critical to maximizing cycle life.Not only does the BMS protect the Li-Ion forklift battery while charging,it also provides real-time data on forklift battery health and state of charge.

A battery management system can ease the burden of in-house forklift fleet management by providing real-time data for preventive maintenance.When paired with a telematics unit,data from the BMS can be accessed through the cloud to gain insights into forklift usage patterns.

Remote monitoring can detect problems before they become serious,reducing or eliminating truck downtime.Because the BMS tracks temperature,state of charge,and battery usage,extracting this data can provide insight into warehouse operations.For example,a closer look at the data might reveal a need to balance workloads across multiple forklifts or improve opportunistic charging habits.

Understanding forklift battery data can help operations managers make informed decisions about how to reduce the total cost of batteries in their fleet.

Lead acid batteries do not have a BMS to help notify the forklift operator if there is a problem with the battery.

Lead-acid batteries require a lot of maintenance to get the most out of the battery.This creates unnecessary downtime,disrupting productivity and increasing labor costs.

Some maintenance steps can include:

●Water the battery every one to two weeks

●Check the water to make sure its pH is between 5 and 7

●Balance the battery regularly and ensure that the temperature is controlled throughout the charging process

Lithium-ion batteries,on the other hand,can be maintained through a BMS.BMS automates this process,making it a huge advantage over the potentially dangerous practice of equalizing charging of lead-acid batteries.The battery management system will track the state of charge of the lithium-ion battery and alert the forklift operator when the battery state of charge is low.

These battery management system capabilities,combined with the improved performance offered by lithium-ion technology,make lithium-ion batteries an attractive investment.